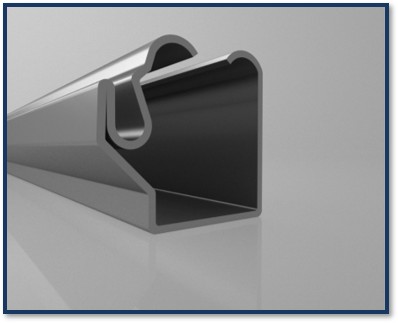

Cable channels are systems consisting of compatible units that enable the safe transportation, securing, and support of insulated electrical cables in the installations of buildings used for energy distribution or communication.

-

What is a Cable Channel?

-

Components of a Cable Channel Roll Forming Line ?

A typical SACFORM line includes:

- Decoiler Unit: Feeds the metal coil into the production line.

- Leveling and Feeding System: Ensures smooth and tensioned material flow.

- Roll Forming Station: Gradually shapes the metal into the desired profile.

- Punching or Perforating Unit: Creates mounting holes or slots.

- Cutting System: Accurately trims the profiles to required lengths.

- Stacking and Output Section: Collects and prepares finished channels for packing or transport.

Each system is modular and configurable, allowing production for different profile types and sizes.

-

What Types of Cable Channels can Be Produced?

- U-Shaped Channels: Strong, versatile, and widely used.

- Perforated Channels: Ventilated and easy to wire.

- DIN Rails: For mounting electrical components.

- Custom Profiles: Adapted to specific project needs.

-

Why Choose Roll forming for Cable Channels?

Roll forming ensures high accuracy, speed, and efficiency, reducing material waste and labor costs while enabling continuous high-volume production.

It is the best solution for scalable and cost-effective cable channel manufacturing. -

What are the Types of Materials and Coatings Used in Cable Channels?

Cable channels can be manufactured from galvanized steel, stainless steel, or aluminium:

- Galvanized steel: Offers strength, durability, and corrosion resistance for long-term outdoor use.

- Stainless steel: Ideal for corrosive or industrial environments.

- Aluminium: Lightweight and corrosion-resistant, perfect for weight-sensitive installations.

SACFORM lines are capable of handling all three materials with precision, ensuring high-quality profiles for diverse applications.

-

Where are Cable Channels Used?

- Industrial plants and factories

- Commercial buildings and offices

- Electrical panels and control cabinets

- Data centers and server rooms

- Infrastructure and wiring projects

They ensure safe, organized, and durable cable management.

-

What Are the Advantages of Using Cable Channels?

- Cost Efficiency

Roll forming minimizes material loss, labor costs, and production time, making it a more economical solution compared to traditional fabrication methods.

- High Precision

Each channel is formed through carefully engineered roll stations, ensuring consistent thickness, exact dimensions, and smooth surface finishes.

- Continuous High-Speed Production

SACFORM roll forming lines are designed for 24/7 operation, capable of producing large volumes with minimal downtime.

- Flexible Design Options

Lines can be customized for profile dimensions, perforation patterns, and material types, providing maximum adaptability for different customer requirements.