- Cost-Effective Production

Roll forming minimizes material waste, labor cost, and production time, offering a more economical solution than traditional fabrication methods.

This enables longer road coverage and safer highways with lower investment costs.

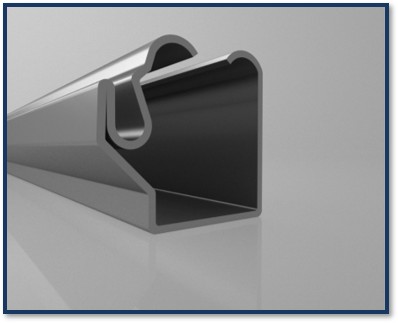

- High Precision and Consistency

Each barrier profile is formed through precisely engineered roll stations, ensuring dimensional accuracy, uniform thickness, and excellent surface finish.

- High-Speed and Continuous Operation

SACFORM roll forming lines are designed for 24/7 industrial operation, capable of high-volume production with minimal downtime.

- Flexible Design Options

In addition to standard models, we custom-design and manufacture production lines according to each customer’s specific requirements — supported by innovative and production-friendly R&D solutions.