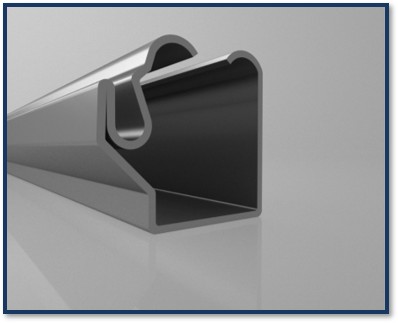

A highway sound barrier, also known as a freeway noise barrier, refers to panels placed between the noise source and the area affected by noise to provide sound insulation.

-

What is a Highway Sound Barrier?

-

What is the Function of Highway Noise Barriers?

With increasing noise, one of the biggest disadvantages of city life has emerged: NOISE. Noise is a problem that causes many diseases today. The purpose of sound barriers built along highways is to block the noise emitted by vehicles and prevent people from being disturbed.

-

What is The Production Type for Highway Sound Barrier Lines?

SACFORM lines are designed for continuous, automated, high-speed production, capable of producing panel and supporting profiles efficiently.

Optional features include servo feeders, integrated punching stations, and reinforced forming units for specialized sound barrier designs. -

Where are Highway Sound Barriers Used?

- Highways and expressways

- Urban roads and streets

- Bridges and tunnels

- Industrial zones near transportation corridors

These profiles effectively reduce noise pollution, protect residential areas, and ensure structural stability and long-term performance.

-

What are The Advantages of Producing Highway Sound Barrier Profiles Using Roll Forming?

Roll forming provides precision, efficiency, and cost-effectiveness, producing components with minimal material waste and uniform quality.

Continuous operation allows high-volume manufacturing, making it an ideal solution for highway and urban noise barrier production. -

What are The Components of A Sound Barrier Roll Forming Line?

A typical SACFORM line includes:

- Decoiler Unit: Feeds metal coils into the system.

- Leveling and Feeding Unit: Ensures flatness and proper tension.

- Roll Forming Unit: Gradually shapes metal into barrier profiles.

- Punching/Notching Unit: Creates slots, holes, or attachment features.

- Cutting System: Precisely trims panels or profiles to the required lengths.

- Stacking and Output Section: Collects finished components for packaging or transportation.

Lines are modular and adaptable, supporting different profile types and production volumes.

-

What are The Material Options for Sound Barrier Profiles?

- Galvanized Steel: Durable and corrosion-resistant for outdoor use.

- Aluminum: Lightweight and easy to install, resistant to corrosion.

- Stainless Steel: Highly durable, suitable for exposed environments with high aesthetic standards.

SACFORM lines efficiently handle all materials, ensuring precision, quality, and reliability.