Logistics warehouse shelf is an adjustable structure designed for storing materials, typically used for storage purposes. Warehouse racks come in many different designs used to maximize storage space.

-

What is Logistics Warehouse Shelf Roll Forming Line

-

What is The Production Type for Logistics Warehouse Shelving Lines?

SACFORM warehouse shelving lines are designed for continuous, automated, high-speed production.

They efficiently produce upright posts, beams, and panels, with quick changeover capabilities and optional features like servo feeders and integrated punching stations. -

What Types of Shelving Components can be Produced?

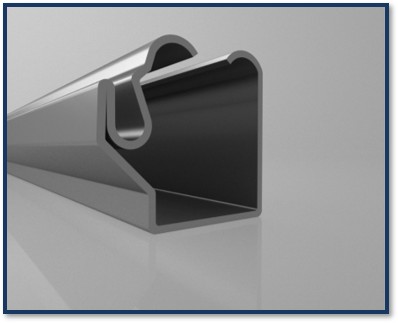

- Upright Posts

- Beams (Step or Box Beams)

- Shelving Panels (Solid, Perforated, Mesh)

- Custom Profiles

Each component can be customized in thickness, width, and galvanization grade to meet project specifications.

-

What Types of Materials Are Used on Warehouse Shelves?

- Galvanized Steel: Durable and corrosion-resistant for long-term use.

- Cold-Rolled Steel: Smooth finish for indoor applications.

- Stainless Steel: High corrosion resistance and aesthetic appeal.

SACFORM lines can process all materials efficiently and accurately, ensuring premium quality shelving components.

-

What are Industrial Warehouse Shelves?

- Warehouses and distribution centers

- Retail stores and supermarkets

- Industrial storage areas

- Logistics and fulfillment centers

- Cold storage or archive facilities

They provide organized, safe, and long-lasting storage solutions, improving inventory management and operational efficiency

-

What are The Components of a Warehouse Shelving Roll Forming Line?

A complete SACFORM line includes:

- Decoiler Unit: Feeds the metal coil into the system.

- Leveling and Feeding Unit: Maintains material flatness and tension.

- Roll Forming Unit: Shapes steel gradually into the desired profiles.

- Punching/Notching Unit: Creates bolt holes or slots for assembly.

- Cutting System: Precisely trims components to length.

- Stacking and Output Section: Collects finished products for packing or transport.

Each line is modular and customizable, adaptable for production volume and component types.

-

What are The Advantages of Using a Warehouse Selving System?

Roll forming ensures precision, speed, and cost-effectiveness, with minimal material waste and consistent product quality.

Continuous operation allows high-volume production, making it the most scalable solution for warehouse shelving manufacturing.