A solar panel is a technology used to convert solar energy into electrical energy. Solar energy is the largest and most continuously available source of energy on Earth. A solar panel is a technology developed to utilize this energy.

-

What is a Solar Panel ?

-

What is The Production Type for Solar Panel C-Profile Lines?

SACFORM lines are designed for continuous, automated, high-speed production, producing standard and reinforced C-profiles efficiently.

Optional features include servo feeders, integrated punching stations, and custom tooling for specialized profiles. -

What are the Advantages of Solar Panel?

Roll forming provides high precision, efficiency, and cost-effectiveness, producing profiles with minimal material waste and uniform quality.

Continuous operation allows for high-volume production, making it the ideal solution for solar mounting profile manufacturing. -

Where are Solar Panel C-Profiles Used?

- Rooftop solar panel installations

- Ground-mounted solar farms

- Industrial solar power plants

- Residential or commercial solar structures

They provide structural integrity, durability, and precise alignment, ensuring the safety and efficiency of solar panel systems.

-

What are The Material Options for Solar C-Profiles?

- Galvanized Steel: Long-lasting and corrosion-resistant.

- Aluminum: Lightweight, easy to handle, and corrosion-resistant.

- Stainless Steel: Highly durable and aesthetically appealing for harsh environments.

SACFORM lines process all materials efficiently and accurately, producing profiles that meet industry standards for solar installations.

-

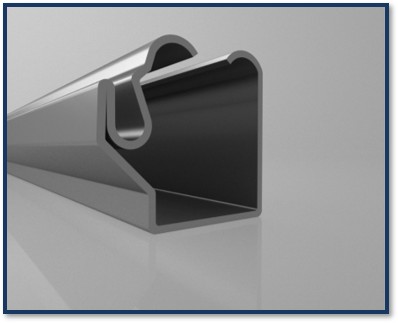

What are The Components of A Solar Panel C-Profile Roll Forming Line?

A typical SACFORM line includes:

- Decoiler Unit: Feeds metal coils into the system.

- Leveling and Feeding Unit: Ensures proper flatness and tension.

- Roll Forming Unit: Gradually shapes the metal into C-profiles.

- Punching/Notching Unit: Creates slots or holes for clamps and connectors.

- Cutting System: Precisely trims profiles to required lengths.

- Stacking and Output Section: Collects and organizes finished profiles for transport.

Lines are modular and customizable, suitable for various production volumes and profile specifications.