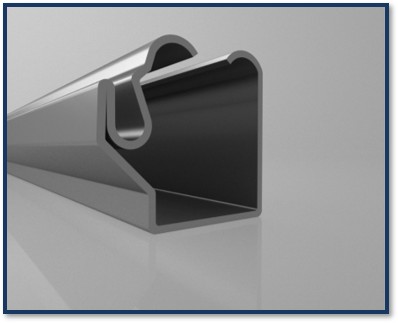

A roll forming machine is a serial production machine used for closed and open profile production. It enables sheet metal to be formed into the desired shape using roll molds, gradually shaping the sheet metal step by step during the forming process. Unlike bending machines, the length of the profile is not limited.

-

What is a Roll Forming Machine?

-

What is the Advantage of Roll Forming Line?

Roll forming allows high precision, efficiency, and cost-effectiveness, with minimal material waste.

Continuous operation supports high-volume manufacturing, making it ideal for projects requiring custom metal profiles. -

What Metals Can a Roll Forming Machine Work With?

Roll forming machines can typically work with metal strips such as sheet metal, galvanized steel, stainless steel, aluminum, and sometimes copper. The type of metal used may vary depending on the machine’s forming capacity and the cylinder structure used.

-

What Products Can Be Produced with a Roll Forming Machine?

Steel construction profiles, automotive parts, shelving systems, solar panel carriers, highway barriers, white goods body elements, ventilation ducts, roof and facade panels, and many other products can be manufactured.

-

Can Roll Forming Machines Produce Custom Profiles?

Yes, modern RollForm machines can produce special profile designs thanks to interchangeable mold systems. Profile production in special geometries is possible with CAD-supported systems.

-

What is The Difference Between Roll Forming Technology and Classic Bending Machines?

Classic machines are generally suitable for single-piece and manual operations. Roll Forming machines, on the other hand, enable continuous and automatic production, offering superior performance in terms of mass production and precision.

-

What are The Types of Roll Forming Machines?

Single-Pass Roll Forming Machines: The most commonly used machine type. It shapes sheet metal into the desired form in a single pass.

Double-Pass Roll Forming Machines: Machines used to produce more complex profiles, shaping the metal by passing it through two different sets of rollers.

Adjustable Roll Forming Machines: Machines that allow adjustments between rollers to suit the production of different profiles, enabling flexible production.

Cutting-Integrated Roll Forming Machines: The forming and cutting processes are performed together, thus reducing production time.

-

Where are Special Design Profiles Used?

Special profiles produced by SACFORM lines are used in:

- Construction frameworks and structural elements

- Industrial machinery and equipment

- Automotive and transportation applications

- Electrical or mechanical assemblies

- Custom architectural and storage solutions

These profiles ensure structural integrity, precise fit, and long-term reliability for demanding industrial applications.

-

What is The Production Type for Special Profile Lines?

SACFORM lines are designed for continuous, high-speed, automated production, capable of handling complex profiles with quick changeovers.

Optional features include servo feeders, integrated punching stations, and welding units for assembly-intensive designs. -

What are The Components of A Special Profile Roll Forming Line?

A typical SACFORM line includes:

- Decoiler Unit: Feeds metal coils into the system.

- Leveling and Feeding Unit: Maintains flatness and proper tension.

- Roll Forming Unit: Shapes the metal into the desired profile gradually.

- Punching/Notching Unit: Adds holes, slots, or other functional features.

- Cutting System: Precisely trims profiles to the specified length.

- Stacking and Output Section: Collects and prepares finished profiles for transport.

Each line is modular and customizable, allowing adaptation to different profile types and production volumes.